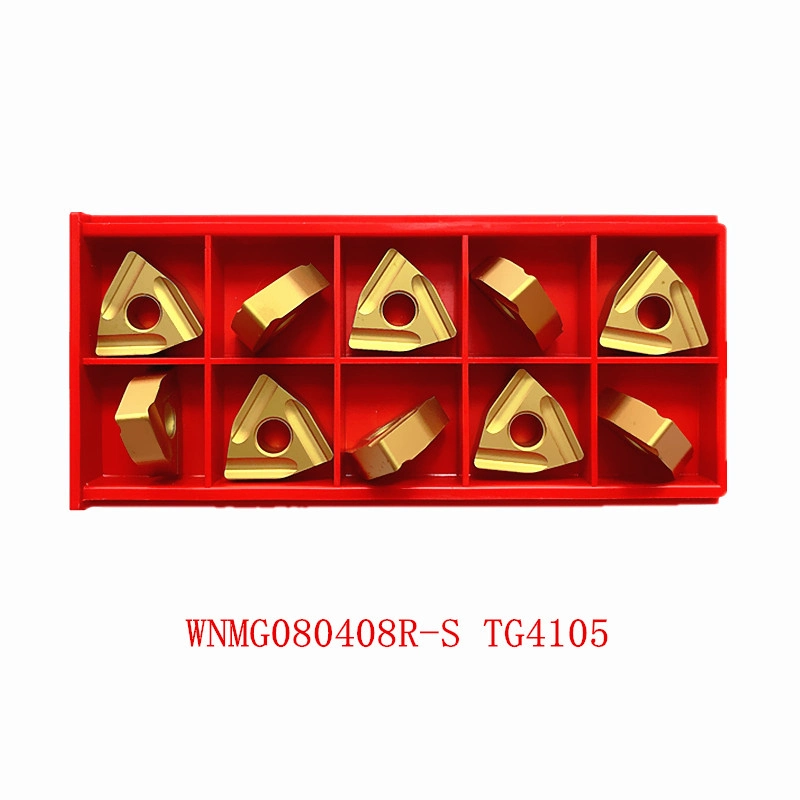

WNMG 431 Tungsten Carbide Turning Inserts

Designed for steel, WNMG 431 tungsten carbide turning inserts offer a variety of benefits:

Multi-edge geometry: These inserts feature a triangular negative double-sided geometry.

Versatile: Suitable for a wide range of steels, including alloy steels, they are ideal for medium to semi-roughing

applications.

Strong and durable: WNMG 431 inserts extend tool life and resist cutting edge deformation, even in challenging

cutting conditions.

Optimized cutting performance: Precision micro-edge geometry and refined edge lines reduce work hardening

and lower cutting forces.

Advanced coating technology: Innovative nanostructured PVD multi-layer coating for longer cutting time and

reduced built-up edge.

WNMG 431 tungsten carbide turning inserts are designed for efficient machining of steel and stainless steel. Featuring a trigon negative geometry, these inserts provide six effective cutting edges, enhancing tool life and reducing costs. With a 12.7 mm inscribed circle diameter and a corner radius of 0.4 mm, they are suitable for medium to rough turning applications. The inserts are optimized for high cutting speeds and feature advanced coatings that improve wear resistance and reduce built-up edge. Their robust design ensures reliable performance in various machining conditions, making them a versatile choice for manufacturers.

| Model | L | ØI.C | T | Ød | Re |

| WNMG060404 | 6.5 | 9.525 | 4.76 | 3.81 | 0.4 |

| WNMG060408 | 6.5 | 9.525 | 4.76 | 3.81 | 0.8 |

| WNMG060412 | 6.5 | 9.525 | 4.76 | 3.81 | 1.2 |

| WNMG080404 | 8.7 | 12.7 | 4.76 | 5.16 | 0.4 |

| WNMG080408 | 8.7 | 12.7 | 4.76 | 5.16 | 0.8 |

| WNMG080412 | 8.7 | 12.7 | 4.76 | 5.16 | 1.2 |

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible