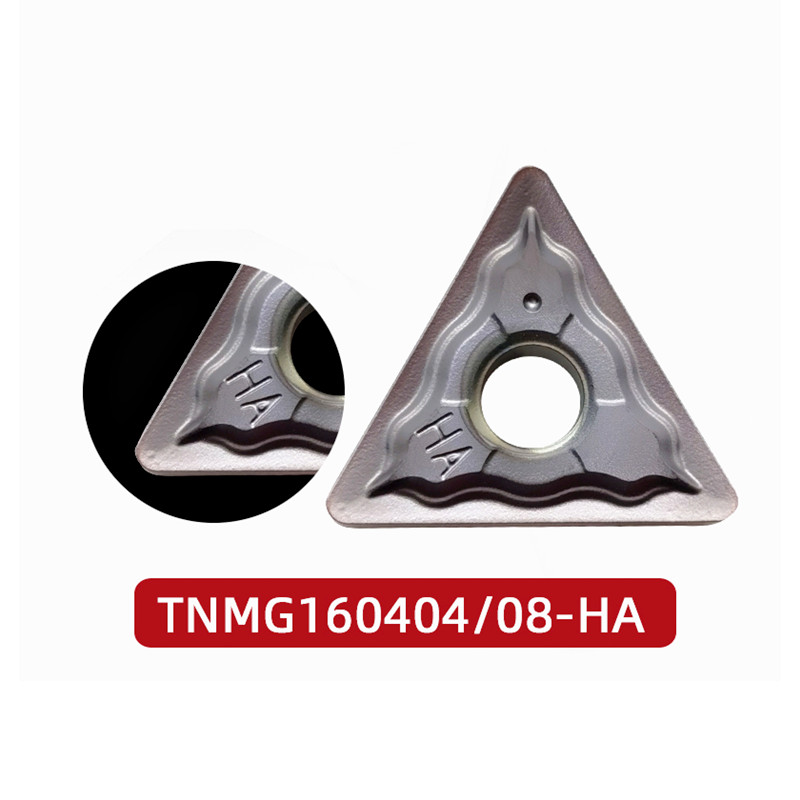

TNMG CNC Lathes Turning Tools

TNMG inserts are a popular choice for machining stainless steel because they offer several benefits:

Versatility: TNMG inserts are designed to handle a wide range of materials, including stainless steels, which are

known for their toughness and corrosion resistance.

Efficiency: These indexable inserts are designed for high metal removal rates, which significantly improves productivity

in turning applications.

Long tool life: TNMG inserts are made of carbide, which is known for its hardness and wear resistance, compared to

tools made of other materials

Consistent surface finish: The precise geometry of TNMG inserts helps achieve a high-quality surface finish on

machined components

Cost-effectiveness: Extended tool life and reduced maintenance costs make TNMG inserts a cost-effective choice.

TNMG carbide inserts are triangular-shaped with a negative rake angle, suitable for a wide range of materials including stainless steel and cast iron. The TNMG 331 insert has an inscribed circle diameter (IC) of 3/8", a thickness (S) of 3/16", and a corner radius (r) of 1/64". These inserts offer up to six cutting edges and are secured via a cylindrical fixing hole, making them versatile for various turning operations. The TNMG 331-PM T9215 grade, for instance, features a negative relief angle and M class, designed for medium cutting with materials such as steel and stainless steel 。Advanced coatings like TiCN+Al2O3+TiN enhance wear resistance and extend tool life, providing reliable performance in high-speed machining

Related News

Submitted successfully

We will contact you as soon as possible